Sign up for smart news, insights, and analysis on the biggest financial stories of the day.

They say everything is bigger in Texas, including the fallout from natural disasters.

Texas has thawed-out from last month’s record-setting winter storm, but the fallout from shutdowns in the state’s massive petrochemical industry continues to intensify.

Lone Star Problems

On top of being the largest energy producer in the states, Texas has become a major player in the global plastics market (many plastics are derived from natural gas and other fossil-fuel byproducts).

The February cold snap — where temperatures across the state fell into a deep freeze — brought unplanned shutdowns to petrochemical plants serving the plastics industry. For industries that rely on plastics (which don’t?), the fallout has been devastating:

- Prices of polyvinyl chloride (PVC) for example, have more than doubled since last summer.

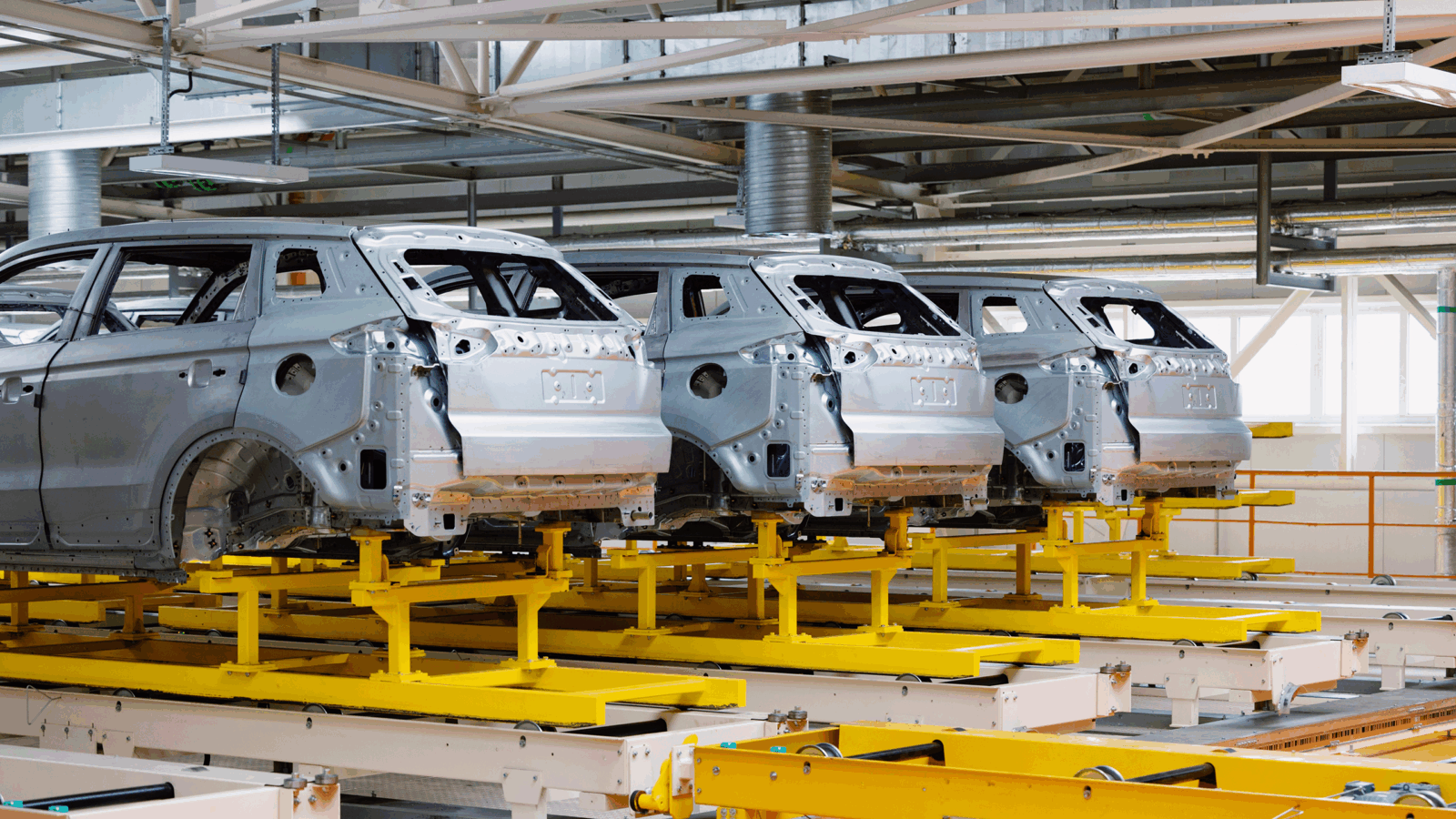

- Citing supply chain issues, Honda said yesterday it will halt car production at several U.S. and Canadian plants next week. Toyota expects to take a hit as well.

- To add insult to injury, hospital supplier Premier said there’s a shortage of the containers used to hold needles, just as they’re at peak demand due to vaccination efforts.

Kristen Hays of S&P Global Platts added color to devastation, “The outcome was worse than even the worst hurricanes, including Hurricane Harvey.”

The Careful Restart

Restarting a petrochemical plant isn’t like hitting restart on a frozen Macbook. Reopening at plants has been delayed for weeks as crews work to check pipes for leaks and damage from the storm — an extremely high stakes and dangerous process.

Hector Rivero of the Texas Chemical Council told the WSJ, restarting a petrochemical plant “isn’t as simple as flipping a switch.”

the takeaway

Next time an unprecedented blizzard hits, stock up on your canned goods and, er, polyethylene?