Apple Leads Manufacturing Pivot to India

Apple shifting production to India is just the latest sign that the world’s most populous nation may be a winner in global trade reordering.

Sign up for smart news, insights, and analysis on the biggest financial stories of the day.

Thanks to the trade war, Apple suddenly has a China problem. Its solution? India.

Last week, the Financial Times reported that Apple is planning to shift the assembly process for all US-sold iPhones from China to India by the end of next year. And, on Tuesday, Reuters reported that production has already started at one southern India plant, with shipments expected as soon as May. It’s just the latest sign that the world’s most populous nation could end up an inadvertent winner amid the global trade reordering.

An Apple Plant a Day…

To put a spin on the old saying: International mega-corporations plan, trade warriors laugh. Apple spent decades and billions of dollars building a world-beating production line for the single most successful consumer electronic device of all time in China. And, in just a few pen strokes (or, should we say, Truth Social posts?), the White House crushed its entire business model with 145% tariffs levied on Chinese imports.

Apple, of course, has been planning ahead. The Cupertino, California-based giant has been slowly diversifying its supply chains away from the Middle Kingdom for years, opening its first iPhone manufacturing plant in India back in 2017. India now assembles about 18% of the roughly 230 million iPhones shipped every year, according to Counterpoint Research. Assembling all of the roughly 60 million iPhones sold in the US every year will likely require Apple to double its current manufacturing capacity in India, according to the FT. It may just be enough for Apple to stave off raising the price of an iPhone, which has held roughly steady for years now:

- While data from industry research firm TechInsights seen by the FT suggest that tariffs could drive the cost of an iPhone 17 up 30% by the second half of the year, Morgan Stanley analysts say leaning heavier on India assembly plants, as well as sharing the burden of rising costs with suppliers, could help Apple maintain its current pricing. (And for reference: Even with a current 26% tariff rate on Indian imports, assembling iPhones in India is still likely to be far cheaper than assembling them in the US.)

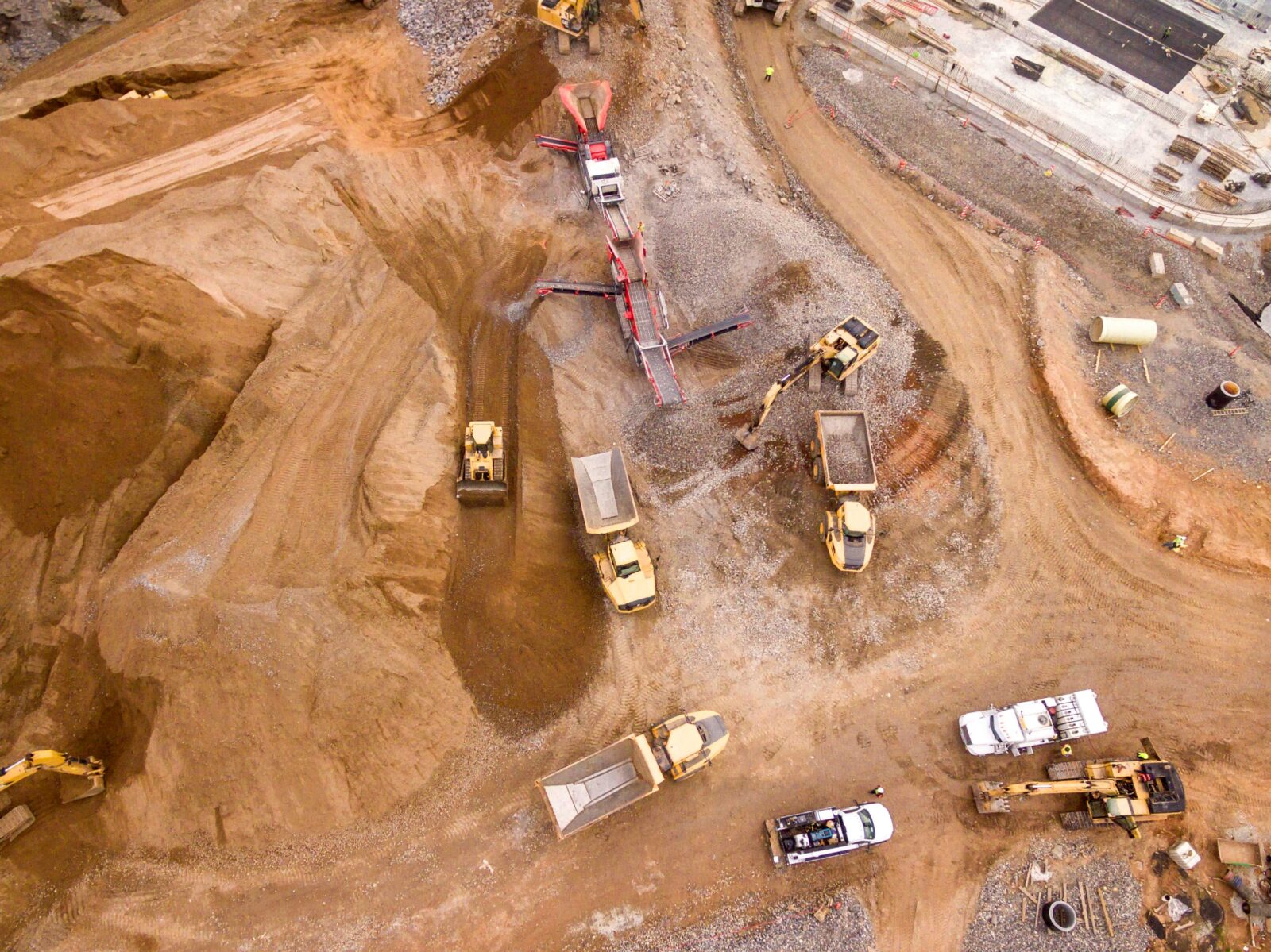

- Apple isn’t wasting any time: In addition to the factory that opened Tuesday, Reuters reports that Foxconn has begun construction of a $2.6 billion facility in Bengaluru, India, which will be capable of assembling as many as 500 iPhones per hour.

Still, not everyone is buying the India pivot as a perfect solution. In a note to clients last week, MoffettNathanson analysts wrote, “The bottom line is a global trade war is a two-front battle, impacting costs and sales. Moving assembly to India might (and we emphasize might) help with the former. The latter may ultimately be the bigger issue.”

Start of the Deal: The 26% tariff on Indian imports may not hold, either. US Treasury Secretary Scott Bessent said Tuesday that the White House is “very close” to a trade deal with India, and Reuters reported that Indian trade officials are offering a rarely-granted “forward most-favored-nation” clause to the US as a sweetener to hasten talks. Perhaps India’s trade negotiators have hired advisors at Goldman Sachs, who, according to a Wall Street Journal report earlier this week, have been advising nation-clients that any form of “symbolic concessions” could be enough to quickly settle trade talks.