The Watchful Eye of Airbus

Airbus wants to get up close and personal with it’s aircraft builders.

Sign up to uncover the latest in emerging technology.

Airbus wants to get up close and personal with the workers assembling its aircraft.

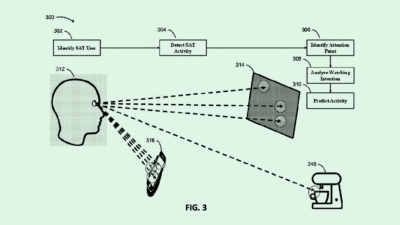

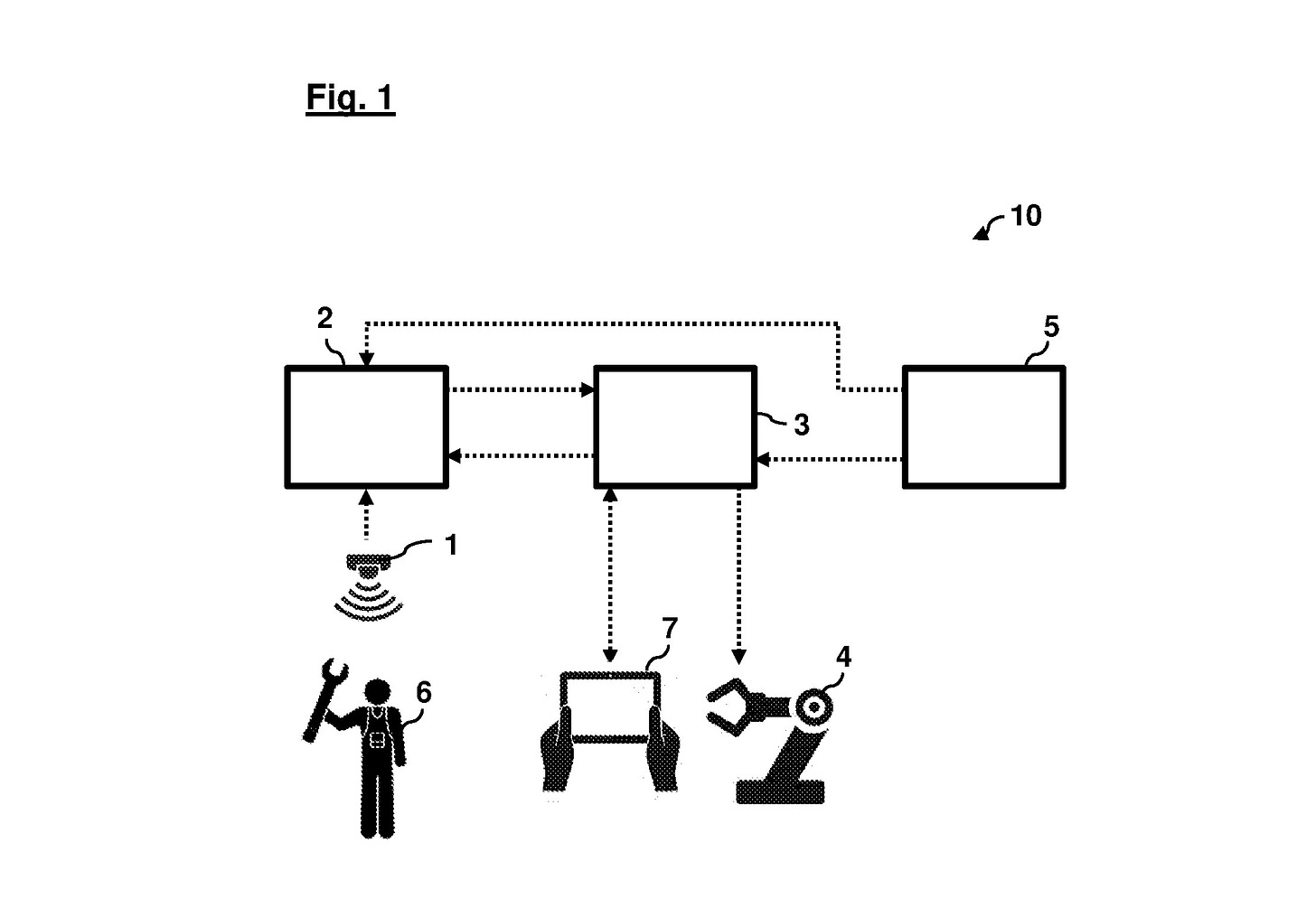

The company is seeking to patent a system for “cognitive assistance” in the manual assembly of an aircraft. Here’s how it works: Sensors, such as cameras, EEGs and eye tracking tech, monitor physical and physiological data on a worker that’s assembling an aircraft. That data is continuously fed to a “cognitive model,” which makes real-time predictions of that person’s expected behavior during the aircraft assembly process.

This information, in turn, controls the actions of different machines in the assembly process. For example, if a worker takes an unexpected break, the system reacts to this change and automatically halts operations of the machines that they’re working with. This would help workers avoid any injuries caused by automation in manufacturing.

By making industrial machines more reactive, Airbus said that its tech could help overcome fundamental challenges of human-machine collaboration in manufacturing environments, improving things like safety and assembly quality. This system also has the potential to majorly cut labor costs, as it can be applied to the highly specific and typically “personnel intensive” tasks that aircraft manufacturing demands.

“Control systems of today’s collaborative robots are often unable to handle the prediction and incorporation of human behavior in complex assembly situations” Airbus said in its filing. “The highly demanding requirements on the quality of the assembled components pose another hurdle.”

Airbus’s patent is the latest of several filings from tech firms that aim to implement AI into a factory setting. Baidu sought to patent an AI model that could detect whether or not workers are wearing safety gear, and Airbus rival Boeing filed a patent application for an AR and AI-based system that automatically detects anomalies during aircraft inspections.

What set’s Airbus’s patent apart is that it essentially aims to automate the job of a factory foreman, said Rhonda Dibachi, CEO of manufacturing-as-a-service company HeyScottie. Rather than implementing AI to control just the machinery itself, this system does the job of top-down management by overseeing the interaction between the human worker and the machine.

“It enables partial automation of assembly operations – that is a foreman’s job,” said Dibachi. “It is no longer just doing single operations, it’s actually doing an assembly(line). This is lights-out management, which is a fascinating next step.”

As skilled manufacturing workers become harder to find, embedding robotics further up the chain will only further reduce the heavy cost of labor, said Dibachi. While the startup costs of implementing a system like Airbus’s can be prohibitive, “everybody who is adapting robotics in any sense … doing it because of labor.”

But one thing this patent doesn’t explicitly note, Dibachi pointed out, is an override function. AI-based tools can go haywire without oversight. If a factory’s foreman is replaced by AI, employees should have the capability to hit the kill switch if something goes wrong.

Another consideration: While tech like this has the potential to improve factory safety with the right precautions in place, the intense monitoring involved in Airbus’s system does involve employees giving up a certain level of privacy, bringing up the ever-consistent question of cost versus benefit involved with AI and data privacy.

Whether or not employees will be comfortable with tech that tracks them closely depends on how Airbus presents it to them, said Dibachi. “If there’s an obvious safety link, worker adoption is going to be higher,” she said.

Have any comments, tips or suggestions? Drop us a line! Email at admin@patentdrop.xyz or shoot us a DM on Twitter @patentdrop. If you want to get Patent Drop in your inbox, click here to subscribe.