Sign up for smart news, insights, and analysis on the biggest financial stories of the day.

Electric cars are no longer the future. They’re the here and now.

Governments around the world are lighting a fire under automakers to hasten their transitions to electric. Last year, the Biden administration ushered in a huge bushel of incentives for carmakers to go electric and now the EPA is offering some stick to go with that carrot. Meanwhile, the EU is pushing to phase out new gas guzzlers by 2035, and China has become a world leader in buying and selling EVs by laying on subsidies.

Major automakers are racing towards electrification as well. Earlier this week, GM revealed what it says will be its last new gas-powered model. But as EVs are gradually becoming cheaper and more mainstream, a dark speed bump looms on the horizon. The world’s charging networks remain far from equipped to juice a driving population that’s majority electric.

It’s a fairly sticky chicken-egg situation: To justify building new charging stations, you need a lot more EV drivers on the road than there are today. But one technology appears set to take full advantage of the EV market’s awkward teen stage.

Solar power has long been seen from a consumer perspective as something you bolt on your roof, but the first generation of solar-panel-equipped vehicles is starting to emerge at just the right time.

So that’s what we’ll be taking a look at today, whether solar can piggyback on the rise of EVs, and whether it makes any economic sense. So pop on your shades, here comes the sun.

The Dawn of Solar Power

Solar energy has been around almost as long as electricity itself. The first known scientific observation of a solar-generated voltage was in 1839, and patents for solar-powered engines started to be filed in the US in the 1860s. It wasn’t until 1883 that US inventor Charles Fritts actually built the world’s first solar cell, which managed to convert 1-2% of the solar energy it was absorbing into electricity.

In the intervening centuries, the primary focus has been to get that conversion rate up just a scooch more. By 1960 that conversion rate had crept up to 14%, and today researchers have invented cells that can convert 47% of the energy that shines down on them — although most panels you can get bolted onto your house have a conversion rate of around 22%.

Crucially, while photovoltaic cells have been getting better they’ve also been getting cheaper, particularly over the last decade.

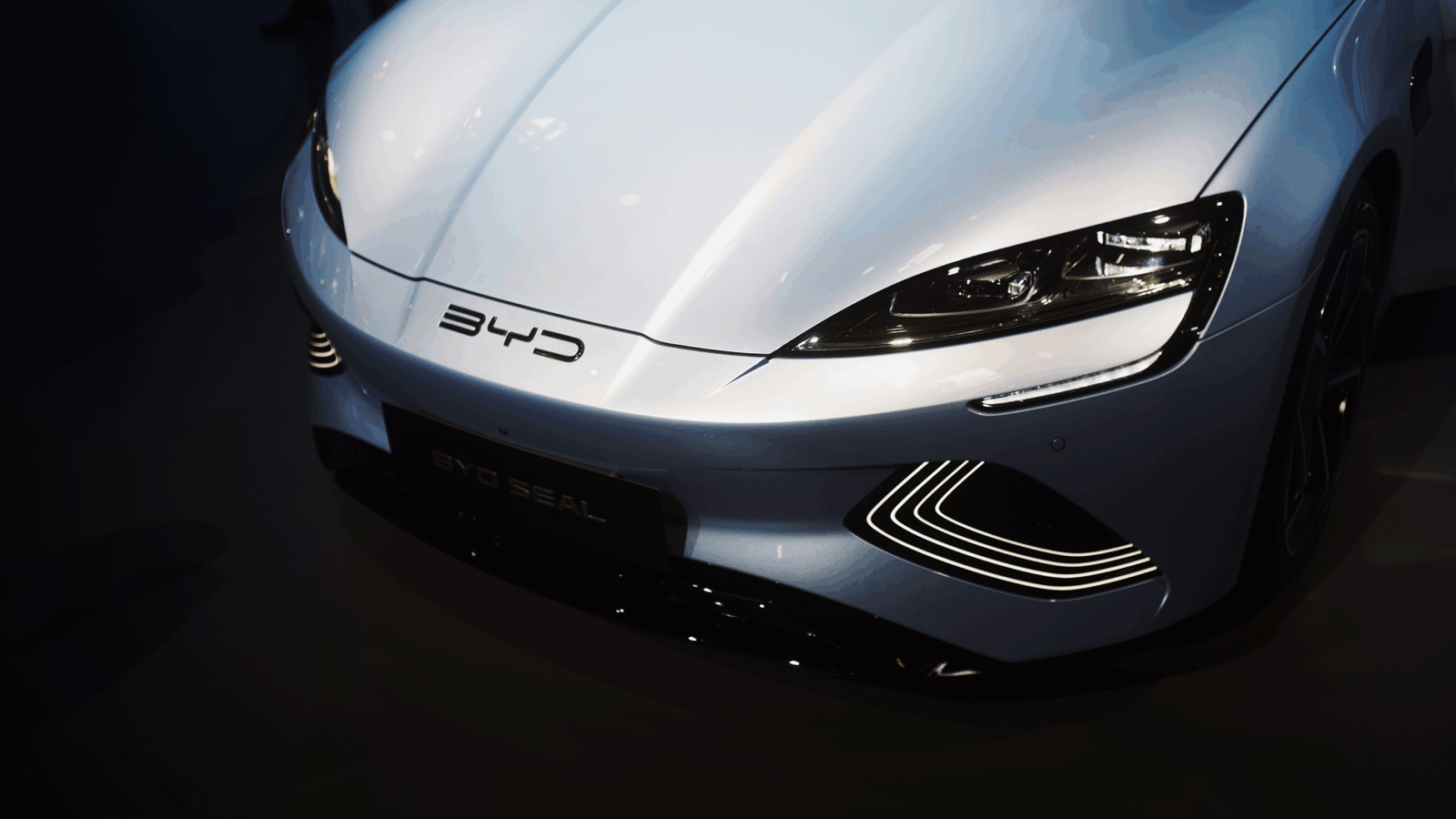

The First Solar Cars

Some automakers are starting to bring models to market with integrated solar cells — i.e. with hoods or roofs that are one big solar cell. They’re not powerful enough yet to power a car on a road trip, but they can make enough juice to give you a boost on your daily commute:

- German company Sono Motors said its solar-integrated model the Sono Sion is expected to begin production in the middle of this year and has touted a $25,000 sticker price on the solar-assisted hatchback. Its solar capabilities add about 15 extra miles a day courtesy of the big, flaming, skyball.

- California-based Aptera is keeping things sci-fi with a three-wheeler that looks like something out of a reboot of Speed Racer. Aptera says its solar model is due to begin production this year as well, with prices starting at $26,000, and drivers will get up to 40 extra miles from its solar capabilities.

“Solar panels are so inexpensive and integrating them into the skins is so easy that once you get over that initial learning curve, those initial couple thousand vehicles out there, it’s hard for me to envision that this won’t be cost-effective,” professor of energy at UC Berkeley Dan Kammen told CNBC.

Prof. Richard Bucknall, head of University College London’s mechanical engineering department, told The Daily Upside he was more skeptical, and not because the sun seldom shines in the UK.

“At the end of the day, you can’t get the energy from the solar cells which makes it viable to put them on a car. You’re better off putting them in a field generating electricity, and then sticking that in the grid. It’s a much more techno-economic solution,” he said.

Bucknall doesn’t think that will stop solar cars from finding a market though.

“At the end of the day, driving a car around London with solar cells is cool,” he said. “Logic doesn’t come into it really. An engineer will tell you, ‘It’s not the right way to do it,’ but that’s not the way people think.”

It’s Not Always Sunny In Amsterdam: Although solar EV manufacturing is starting to crystallize into reality, it’s still a tight balancing act. Dutch company Lightyear started making the first production-ready solar car, the Lightyear 0, at the end of 2022, but it came with an eye-watering $274,000 price tag. The company announced in January it would halt production of the Lightyear 0 and focus instead on bringing a less bank-breaking model, the Lightyear 2, to market in 2025 for around $40,000. Days later Lightyear announced it had filed for bankruptcy.

On April 3, the company announced a rebirth, saying it was rebooting with a slimmed-down team and a fresh injection of investment capital to once again pursue the Lightyear 2.

Trucking Along: Although solar-powered personal vehicles are a novelty, solar has quietly been a part of the logistics industry — where tiny efficiencies scale up — for a while.

Trailar, a UK-based company founded in 2018, has developed a system of adapting existing large vehicles with solar mats. The company affixes the flexible mat on top of the vehicle and then hooks it into the engine, giving it an extra boost whether it’s electric or gas-powered. Trailar’s commercial manager Stuart Porter told The Daily Upside the economics of solar-powered logistics already work because the vehicles have more space to mount solar cells on.

“This is just common sense stuff,” Porter said, adding that public awareness of residential solar panels helps the company sell its product. “People understand how solar panels work, they understand how it works from a residential or a commercial setting for pulling energy.”

For Trailar, switching to electric isn’t just about enhancing a vehicle’s range or combatting charging anxiety. Logistics requires huge amounts of extra energy for the refrigeration of cargo and loading objects into trailers. Solar power is already helping with those ancillary energy needs, and Porter thinks that when EVs start to take over, solar augmentations will just make good business sense.

“People are still going to have to find lightweight power sources to operate their businesses, and all the vans that roll around and go to clean people’s drains or whatever else — when you have an EV van, you can’t then go put a dirty great big fuel compressor on the back of that van to provide that power. So there’s always going to be a need for supplementary power,” he added.

From a decarbonization standpoint, Bucknall is unconvinced solar cells on cars and trucks will make any sort of dent. He believes the best way to push more EVs onto the road is for the EV industry to come up with a standard socket, similar to the USB-C cable for phones (which Apple has recently agreed to roll out in Europe following an EU directive). For this to work fully, he says, you’d need international cooperation.

He does think solar will have a part to play as the world needs to wean itself off fossil fuels. As one example, he pointed to concentrated solar power generation, which uses mirrors and lenses to focus the sun’s rays and generate steam to turn a turbine.

“That is super cool. But you know: solar cells on cars, solar cells on ships, solar cells on lorries, it’s a bit gimmicky to be honest.”