Boeing’s Patent Brings Explainable AI to Manufacturing

“We’re moving away from the black box,” said said Frederick Gertz, founder and CEO of enterprise AI company Collide Technology.

Sign up to uncover the latest in emerging technology.

Boeing wants to know when its planes are going to fall apart – and why.

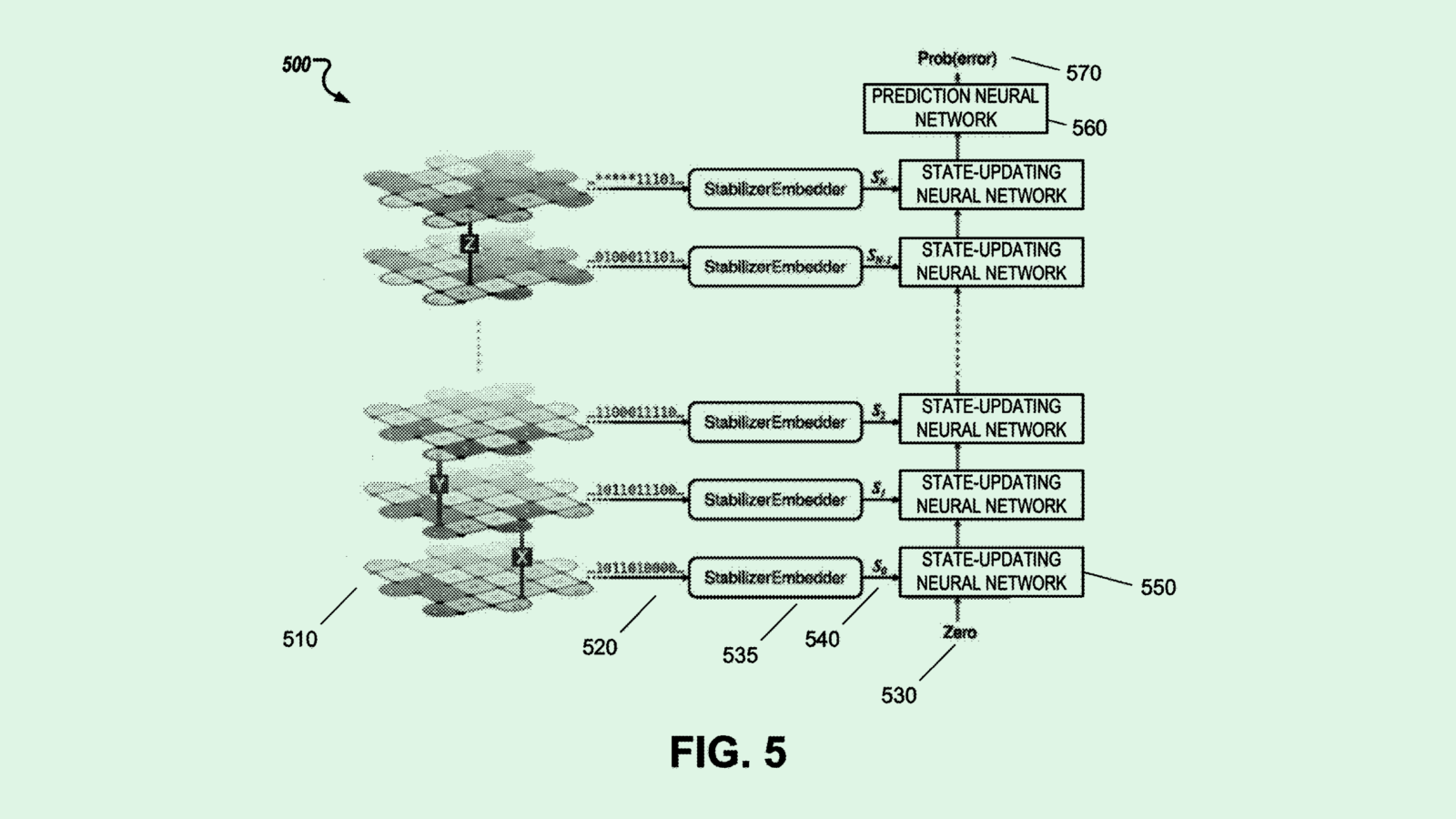

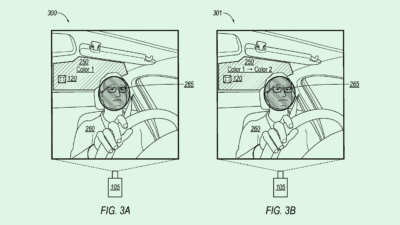

The aerospace manufacturer filed a patent application for vehicle health management using a “counterfactual machine learning model.” Essentially, this system uses an AI model to track when a vehicle surpasses a threshold of needing maintenance.

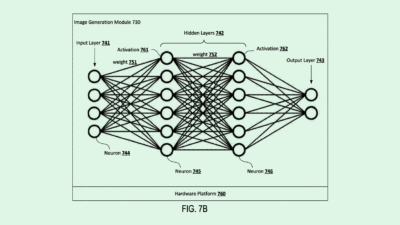

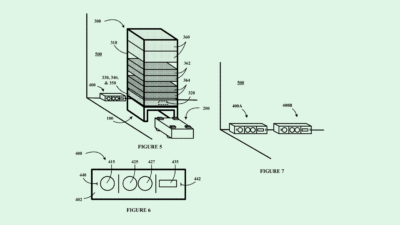

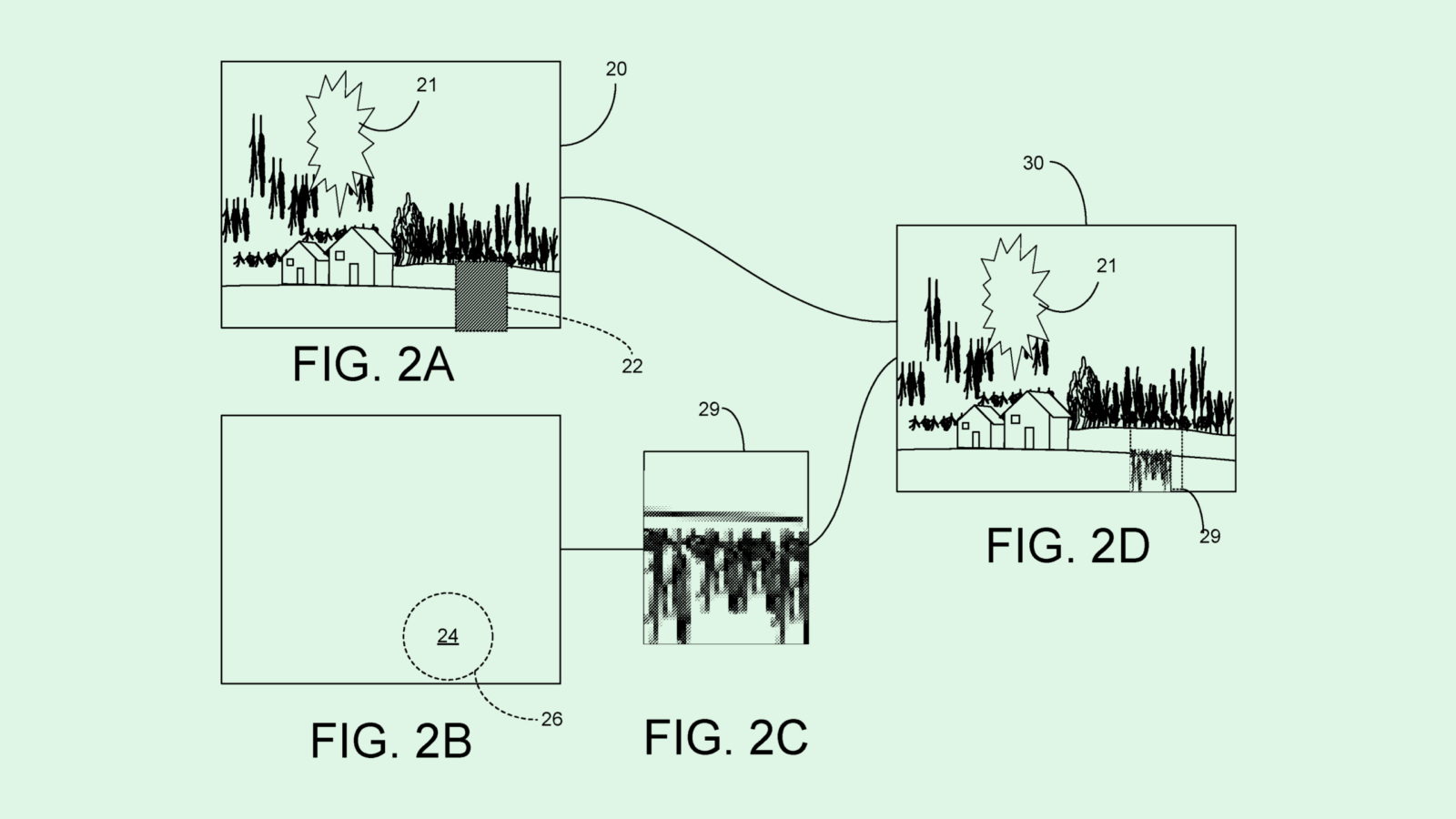

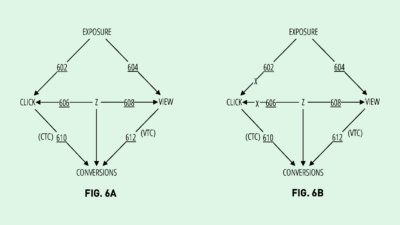

Boeing’s system tracks historical data from a number of physical sensors on an aircraft. This data helps Boeing get a “domain invariant representation” of the vehicle’s condition, i.e. understanding the vehicle’s health across different situations. The “counterfactual” machine learning model is then trained on this data.

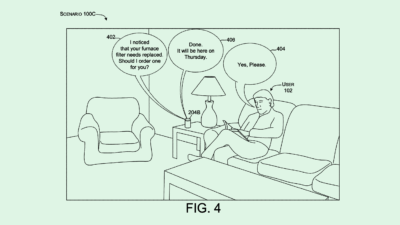

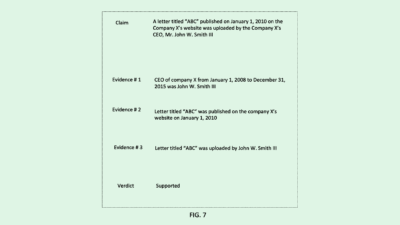

A counterfactual machine learning model simulates different “what-if” scenarios, to help predict outcomes under a variety of different circumstances. This allows the model to explain how it came to certain conclusions, rather than leaving it up to the so-called black box.

Boeing’s system then calculates maintenance thresholds for the components it keeps track of, and selects one based on a certain objective, such as optimizing cost or safety, while also “avoiding part anomalies,” the company said. The system then monitors these sensors to predict when these parts may surpass that threshold and need to be changed or fixed.

Boeing noted that this kind of prediction avoids “reactionary maintenance schedules for unscheduled maintenance,” which can keep an aircraft out of service for longer than they would be on a normal maintenance schedule.

Though AI innovation seems to be happening at the speed of light in every other business sector, manufacturing has taken it slower than the tech world. That’s because software can innovate faster and lighter than anything with hardware or physical elements, said Matt Hudson, CEO of Bildit.

“The physical world isn’t moving any faster,” said Hudson. “Boeing’s not making parts any faster than they currently are.”

That said, machine learning has been a part of manufacturing spaces for a long time, often utilized in maintenance spaces to help predict when things are going to fall apart, before they actually do. This is evident in patents for things like Microsoft’s in-factory stress testing and Boeing’s component fault prediction.

“Virtually every large manufacturer uses a little bit of artificial intelligence and machine learning, and we’re starting to see that trickle down to smaller entities,” said Frederick Gertz, founder and CEO of enterprise AI company Collide Technology.

Boeing’s latest patent signals how explainable AI may play a role on the factory floor, said Gertz. While the filing itself is broad, it’s a sign that manufacturers that use AI want to understand how these models come to their conclusions.

“Where we’re seeing everything start to move is that people are trying to go a little beyond just knowing when something will happen, and start knowing why,” he said. “We’re moving away from the black box.”