Airbus Patent Diagnoses Plane Malfunctions Through Sound

As Boeing faces heat, Airbus may be looking at ways to boost production to meet the surge in demand.

Sign up to uncover the latest in emerging technology.

Not all problems can be seen with the naked eye. Some of them require a deft ear.

European aerospace manufacturer Airbus wants to catch these issues with a patent for an “aircraft sound diagnostic method.” This tech allows Airbus to track abnormal sounds or noise levels throughout an aircraft during inspection.

The manufacturer claims that current inspection methods aren’t doing enough to diagnose anomalous noises within aircraft, as “it can be difficult to know the context of an abnormal noise or of an abnormal noise level when a recording is made during a limited time at the moment when the abnormal noise or the abnormal noise level is heard.”

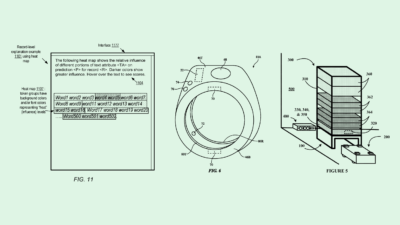

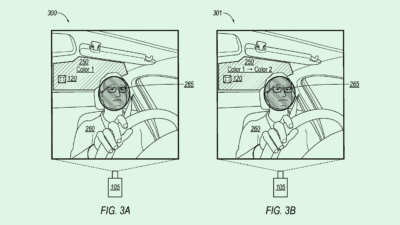

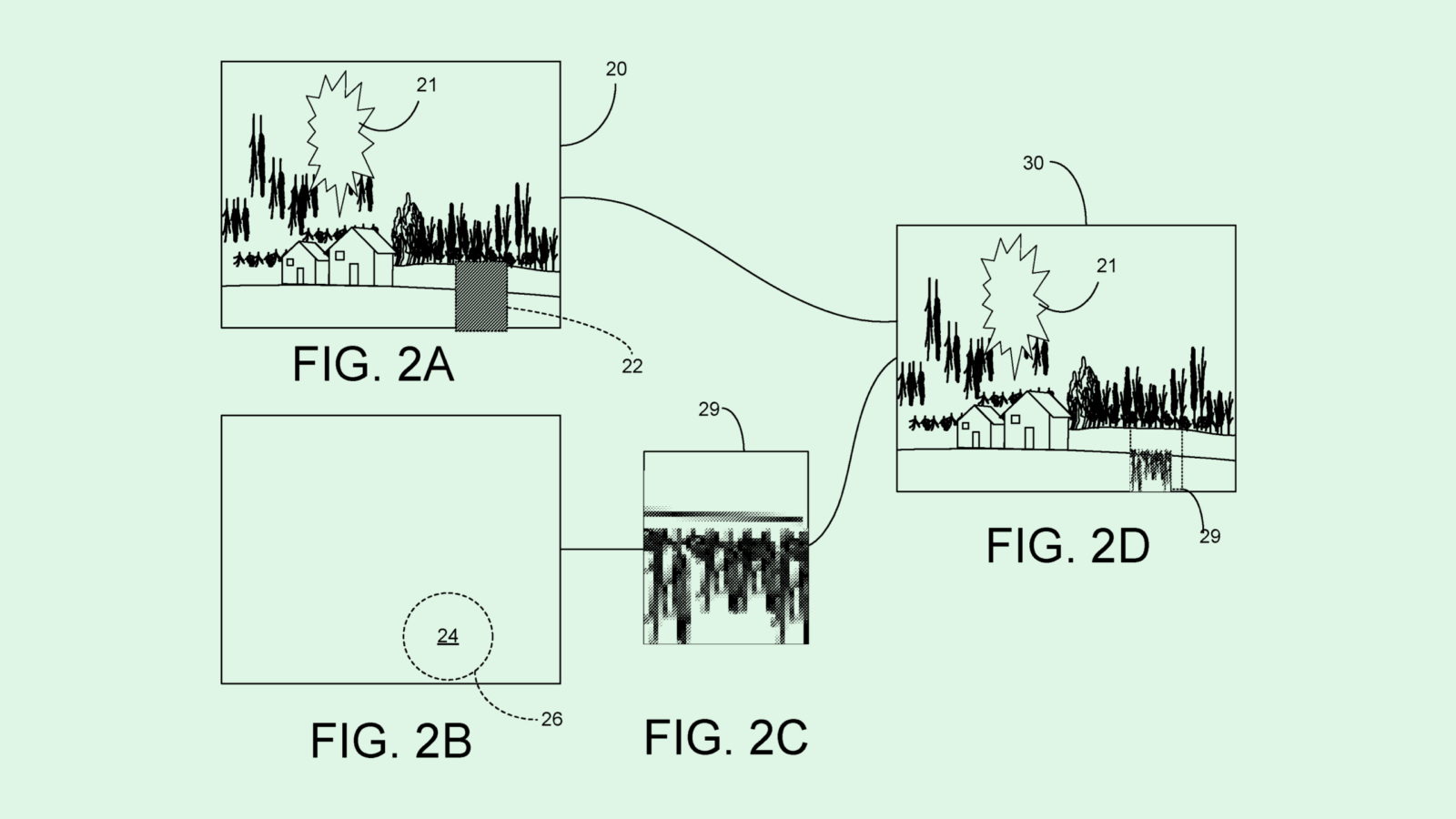

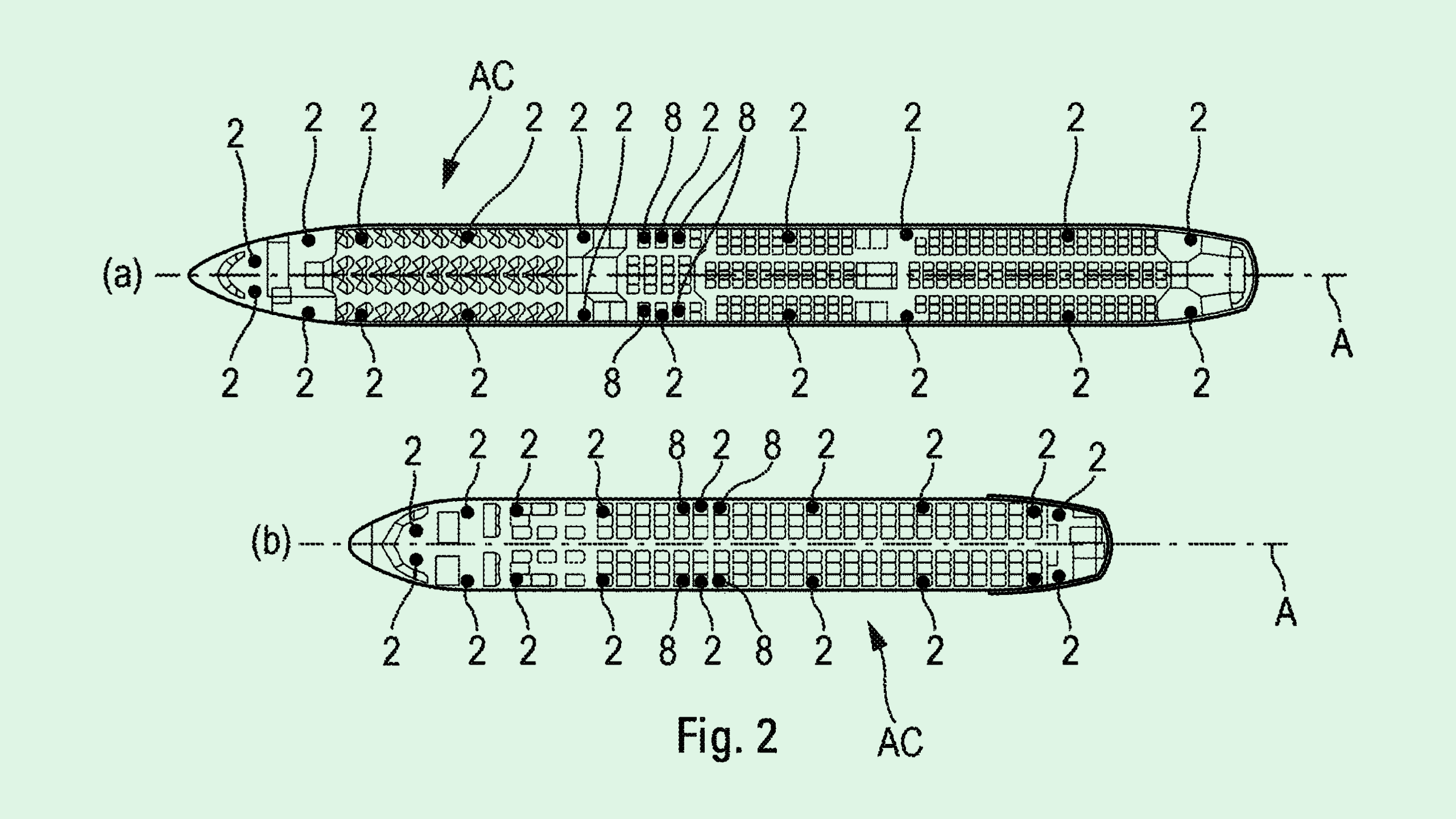

To break it down, Airbus’s method would position several microphones and “vibration sensors” around an aircraft to pick up real-time acoustic and vibrational signals during test flights. Those signals are then sent to a central processor, which generates a sound map based on the signals themselves and the positions of the microphones they came from. The test flight sound map is then compared to a reference sound map, which provides a baseline for normal flight acoustics.

This information is then sent back to the inspector via a real-time display of a graphic representation of the aircraft, which includes the positions of the sensors, the locations where any abnormal sound or vibration signals may have originated, and information about the test flight itself. This system allows Airbus to pin down exactly where any abnormal sounds may come from.

The aerospace manufacturing industry has had more attention in recent months as Boeing, one of the main producers of commercial aircraft, faces endless turmoil relating to its manufacturing and inspection practices following incidents such as a door plug and engine blowouts. Boeing now faces regulator scrutiny and whistleblower reports for its safety practices.

However, as Boeing is Airbus’ main competitor, the bad press seems to be working in its favor. The company delivered 142 planes to customers in the first quarter, around double the output that Boeing reported. The company reaffirmed its output forecast to shareholders last week, on track to deliver 800 planes in 2024.

However, the surge in demand doesn’t come cheap. The company is incurring upfront costs to prepare for the hike in output, investing in thousands of new employees and two additional assembly lines, Boeing Chief Financial Officer Thomas Toepfer told Reuters.

Amid the backlash, looking at more techniques to boost safety and inspection is likely in Airbus’ best interest. This tech may not only allow the company to keep its aircraft safe but also save time and cash as it boosts production and eclipses Boeing.