Boeing Seeks Fault-Tracking Patent Amid Safety Backlash

Though AI has the potential to make troubleshooting issues a much more streamlined process, models still often face accuracy issues.

Sign up to uncover the latest in emerging technology.

Boeing wants to figure out when molehills could become mountains.

The aerospace manufacturer filed a patent application for methods of “fault diagnosis” for complex systems within an aircraft. This tech aims to help minimize mishaps in unscheduled maintenance, particularly aiming to speed up troubleshooting.

Boeing noted that an “improved fault diagnosis system is especially important for unscheduled maintenance such that the troubleshooting process can be expedited in order to reduce the number of flights that have to be delayed or cancelled as a result of maintenance delays.”

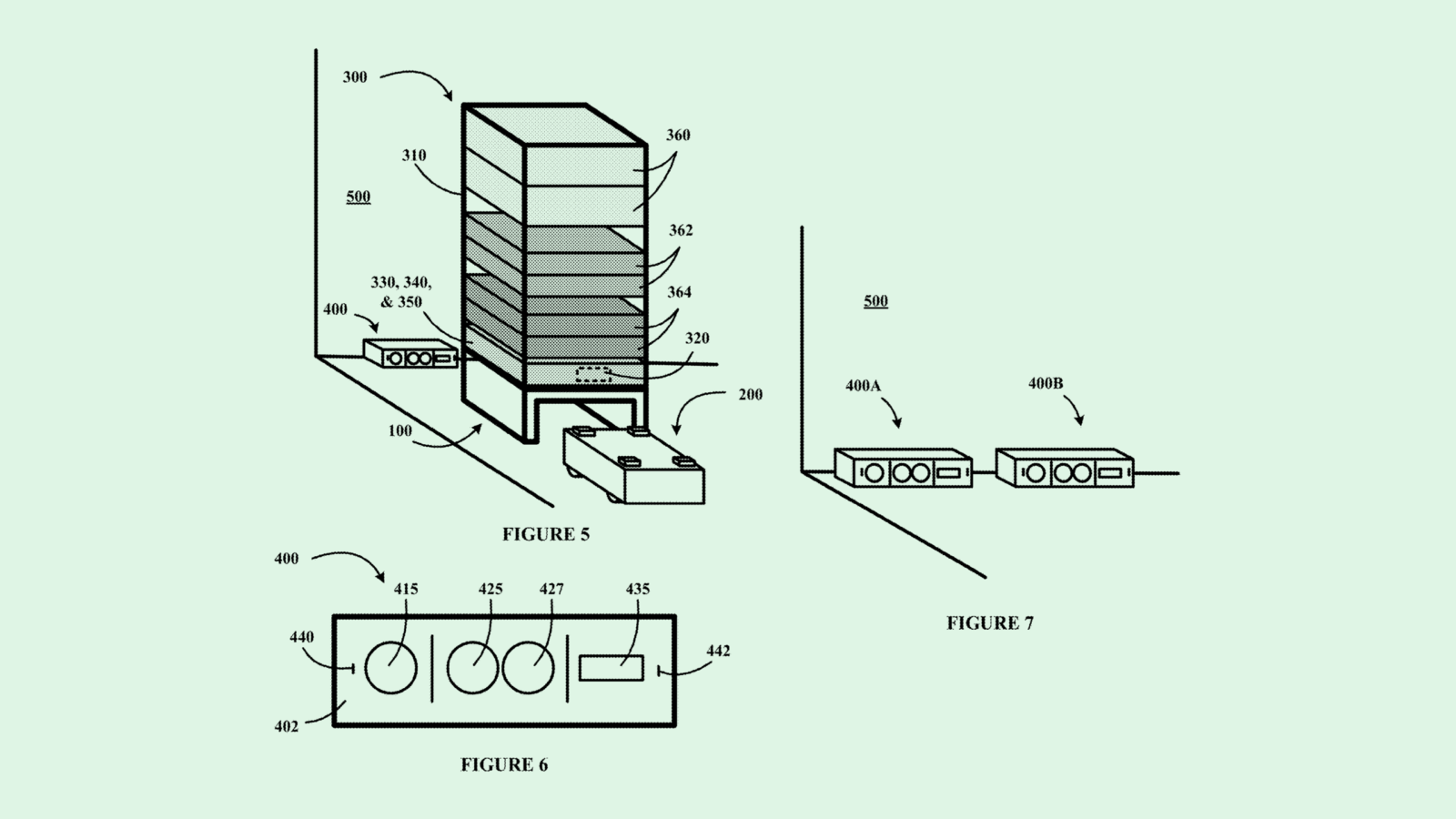

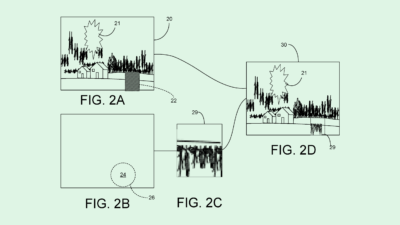

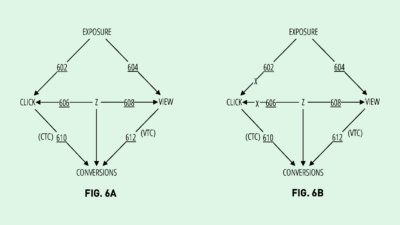

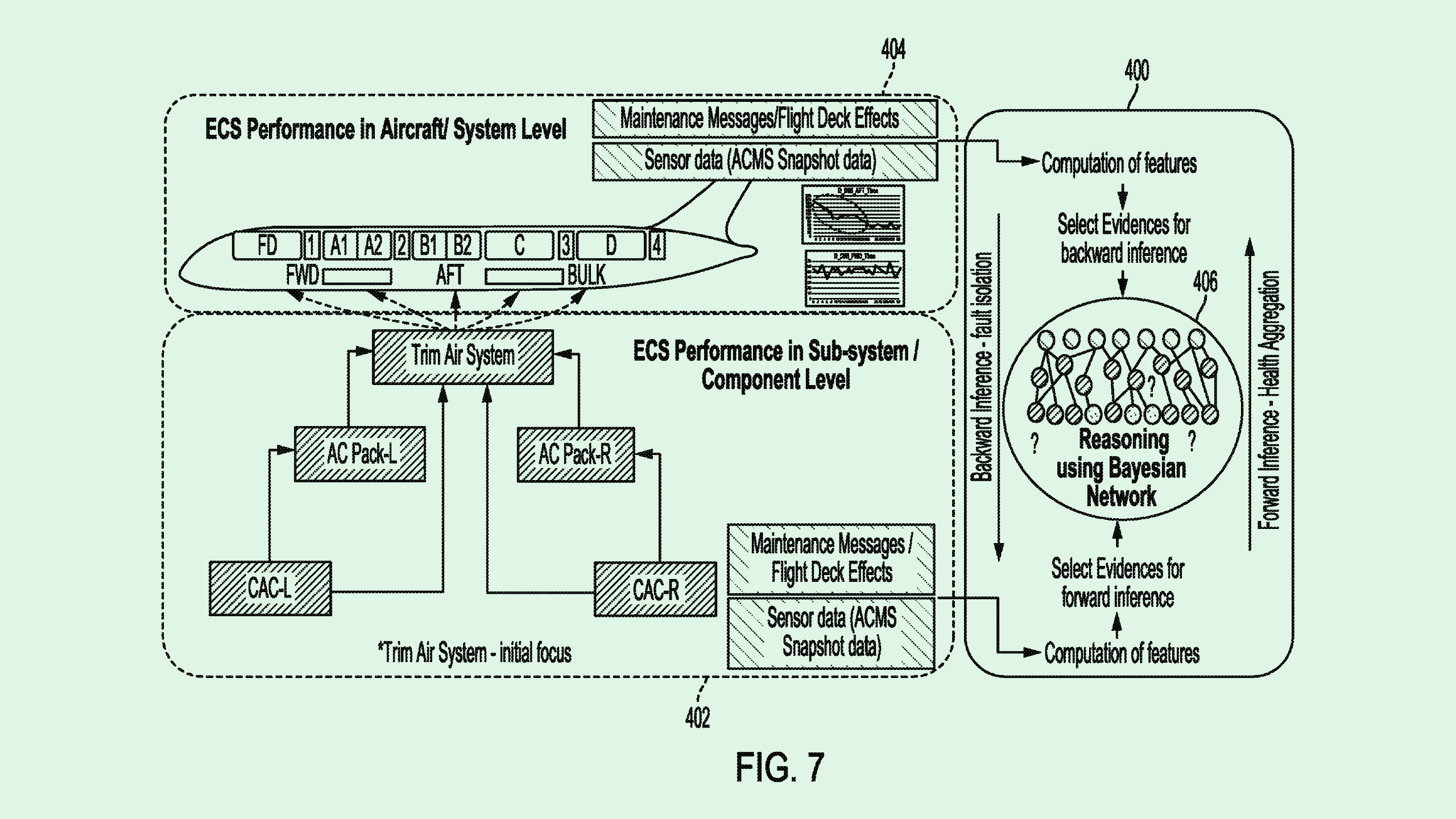

The tech itself is somewhat simple: Boeing’s system continuously monitors operational sensor data that’s indicative of system performance and behavior to determine if certain systems are operating “outside normal ranges or thresholds.”

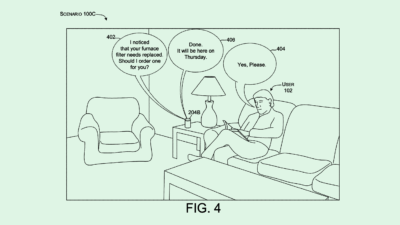

When a deviation is detected, the system determines if a particular mechanism is in a “degraded state.” The degraded conditions of that mechanism, as a “normal state” of operation tracked via machine learning, are fed to a diagnostic model trained to isolate the problem.

Boeing noted that this system could save time and resources needed to track down and solve complex issues in short periods of time, as well as “increase system reliability, safety, maintainability, availability, and affordability.”

Boeing has filed a number of patents that aim to automate maintenance and track anomalies. But the company’s safety practices have been subject to intense scrutiny since the start of this year after a string of incidents and near-disasters have caught the attention of regulators, including a door plug coming loose and engine fires during flights.

After a six-week audit of the company’s manufacturing processes, the Federal Aviation Administration alleged in March that Boeing had 97 instances of noncompliance, according to The New York Times. In May, the agency and the company met to lay out its safety turnaround plan, which included a “significant increase” of safety inspectors and 300 hours’ worth of new training materials.

While patents like these could be particularly helpful at catching breakdowns quickly amid Boeing’s safety woes, they also highlight the growing presence of AI and machine learning in manufacturing and inspection, whether it comes in the form of robotic co-workers, safety monitoring, or surveillance.

And though AI has the potential to make troubleshooting issues a much more streamlined process, models still often face accuracy issues, leading to the false positives and false negatives the tech seeks to negate. In the case of a commercial airline manufacturer, the consequences of these mistakes can be major.