Boeing’s AI Inspector Could Offer a Sharper Look at its Planes

Amid backlash over its safety practices, AI could help Boeing catch what the human eye may miss.

Sign up to uncover the latest in emerging technology.

Boeing may be using machine learning for machine building.

The aerospace manufacturer is seeking to patent a system for “inspecting components” for anomalies using an AI model. Boeing’s system essentially serves as an assistant for inspectors and manufacturers in identifying what parts of an aircraft may go haywire.

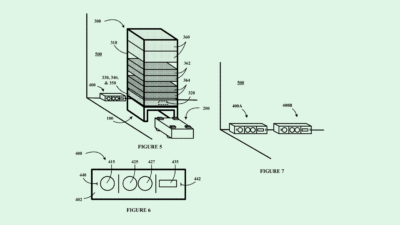

Boeing noted that this method may be particularly useful for identifying problems with aircraft surfaces, such as wings, that may face anomalies ranging from cosmetic deviations to foreign objects to structure damage.

“Current methods for identifying anomalous (e.g., damaged) areas of aircraft surfaces can be tedious and can require the use of heavy equipment,” said Boeing. “Human error can cause false negatives or false positives when identifying anomalous areas of the aircraft.”

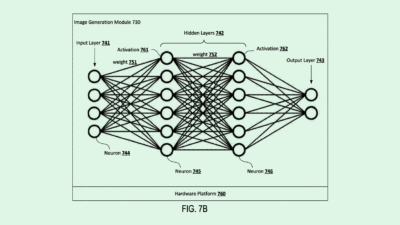

Boeing’s system employs a computational model, such as a neural network, that’s been trained to distinguish anomalous components of an aircraft from normal ones. In order to get the input images, an aerial drone with an attached camera may take pictures of the aircraft’s facade.

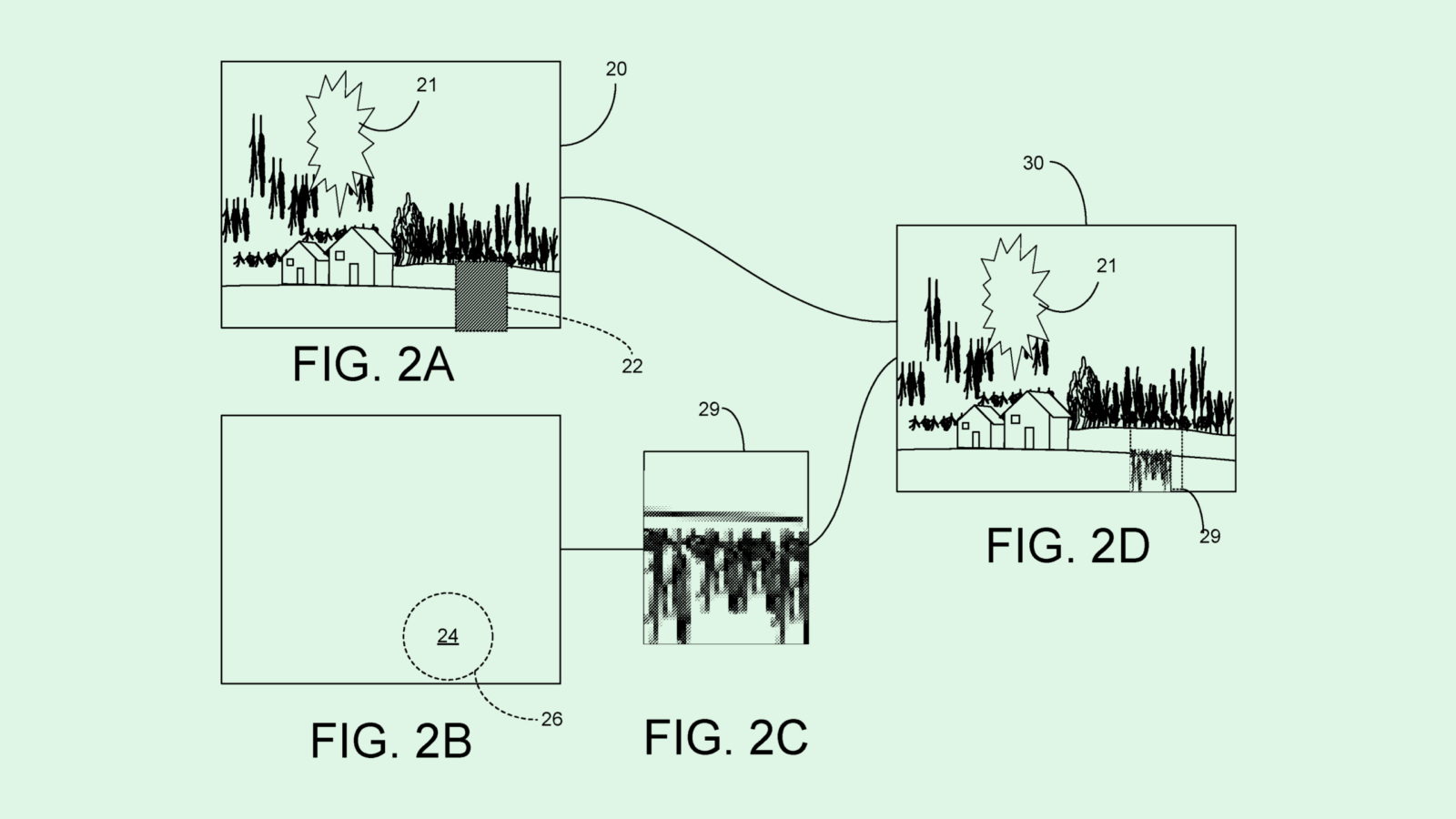

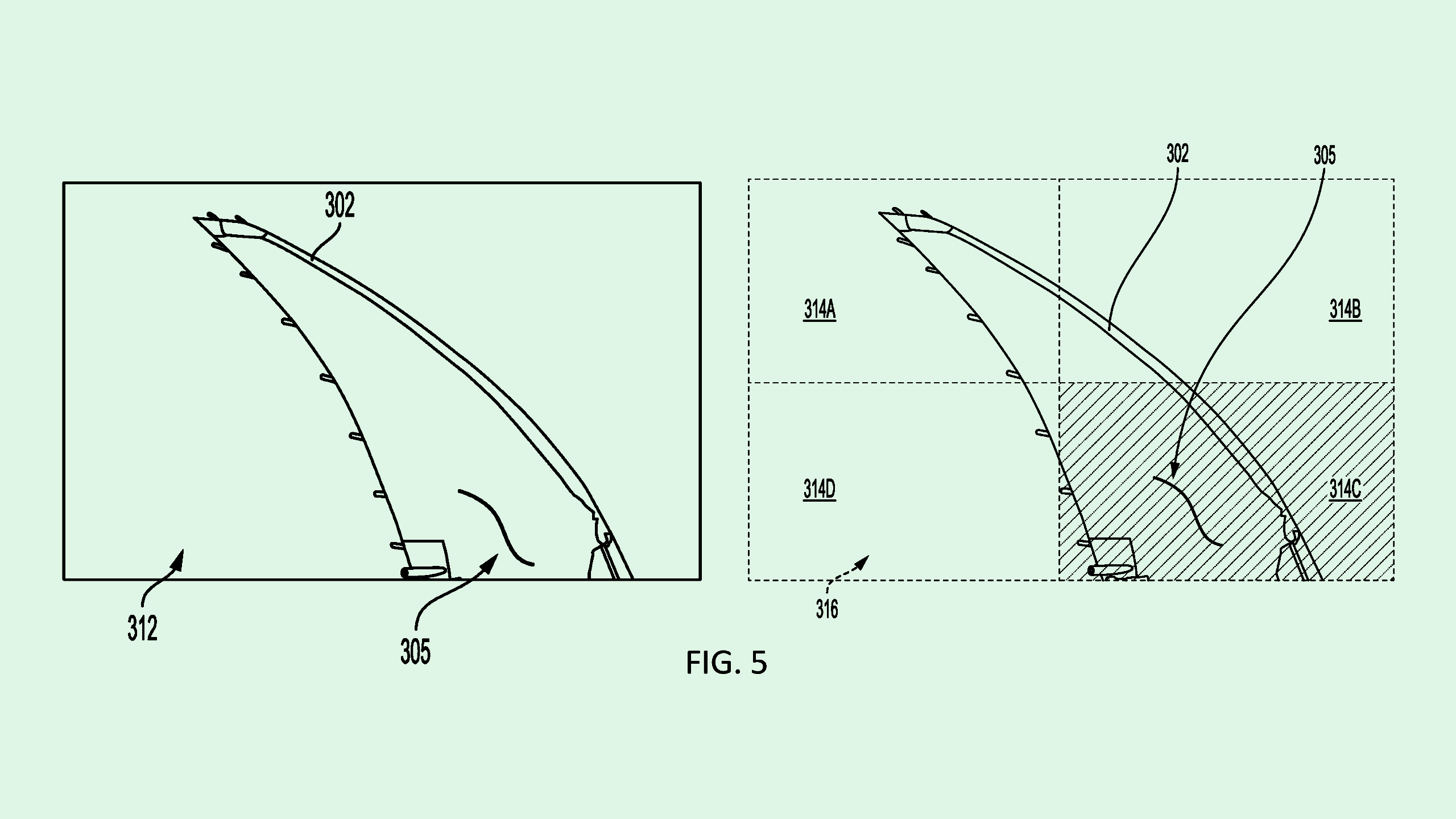

When examining an image, this system compresses its input to have lower resolution, reducing the complexity to only what’s important for analysis. With this, the system does a preliminary assistant to decide whether the component of the aircraft may have something wrong with it.

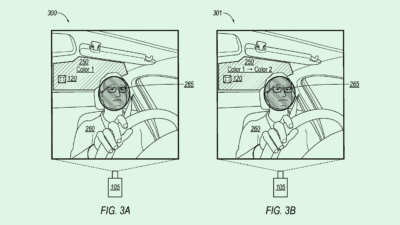

If the model calculates above a certain “confidence level” that something is off in its first analysis, the system uses a higher resolution version of the image for a more granular look at the component to figure out what or where the problem may be. This prediction is finally sent back to the manufacturer or inspector via a user interface. If the model’s predictions end up as a false positive, the system is then retrained.

Finally, this tech can also predict future anomalies by estimating the “number of flight hours that will pass” before something breaks down.

Boeing’s safety practices have come under fire in recent weeks after a 737 Max 9 door plug blew off on an Alaska Airlines flight in early January, leaving a hole in the side of the aircraft in midair. Alaska Airlines CEO Ben Minicucci said that the company found several loose bolts across its 737 Max 9 aircraft following the incident. And weeks later, an Atlas Air Boeing 747 experienced an engine failure soon after take off.

A United Airlines executive VP of finance Gerry Laderman said this week that a general loss of experience and skill across the aviation industry due to Covid-19 may have contributed to Boeing’s issues.

AI could help Boeing catch what the human eye may miss, said Rhonda Dibachi, CEO of Manufacturing-as-a-Service firm HeyScottie. With this patent in particular, by looking at the bigger picture and then zooming into specific parts that exhibit issues could allow for a more thorough inspection.

“The errors seem to be errors of omission in inspection,” she said. “And to the extent that AI can help with that, I think that can only be good. It’s another tool people can use.”

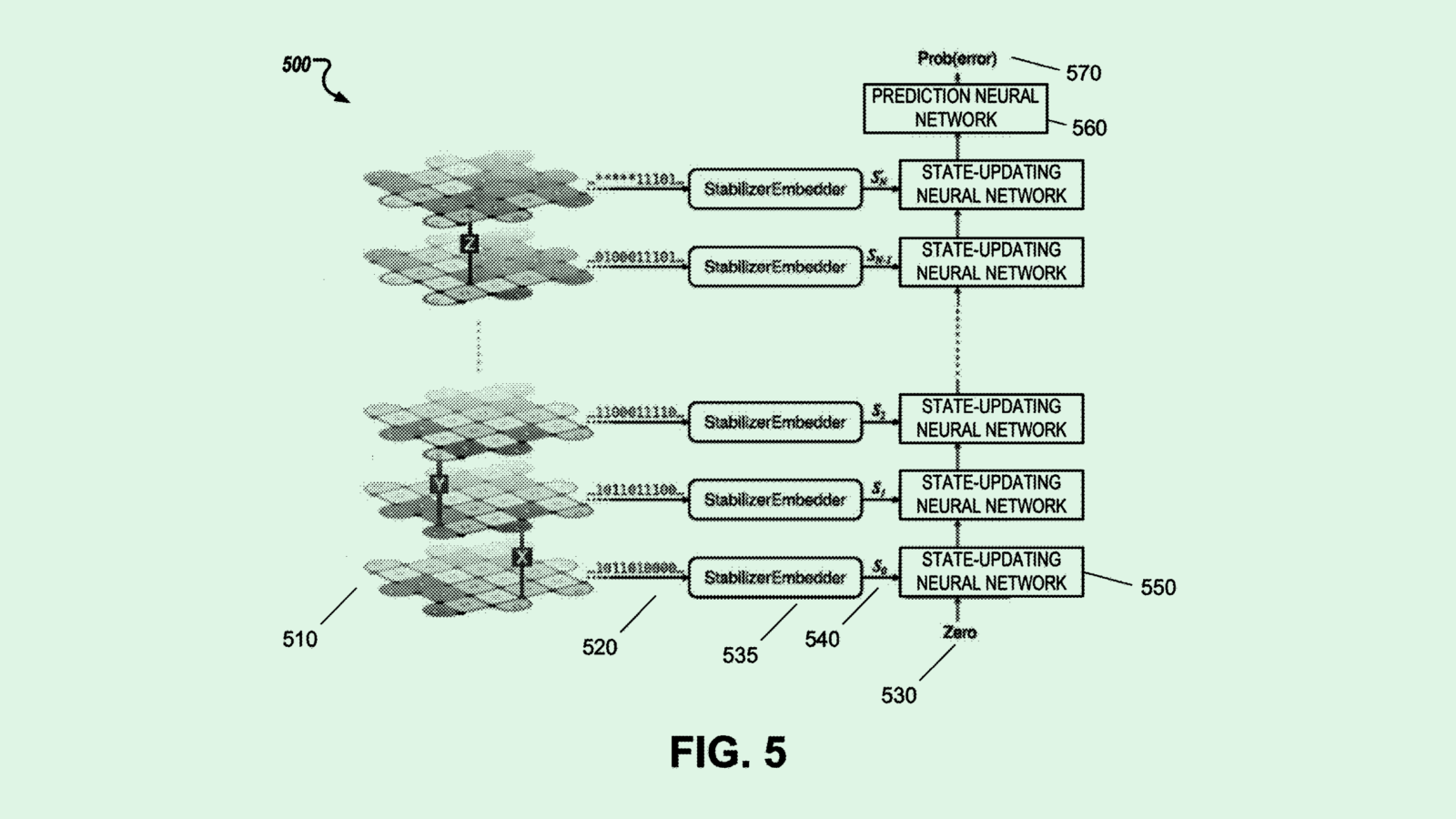

This isn’t the first time we’ve seen Boeing take an interest in bringing AI into its manufacturing processes. The company’s patent history includes machine learning-based component fault prediction and explainable maintenance tracking for “what-if” scenarios.

However, when using AI for inspection specifically, a lot of prior patents in this space are generally for small-scale manufacturing settings, such as semiconductors, said Dibachi. “AI to enhance visual inspection has been around in the manufacturing industries since basically the 90s,” said Dibachi. “That was one of the first AI applications. But I don’t know how prevalent it is in larger-scale manufacturing.”

One potential problem with this patent, she noted, is that it doesn’t seem to mention how it treats inspection of more critical components over others. “If there’s a wing, it’s probably not going to fail in the middle, it’s probably going to fail where it attaches to the fuselage,” she said. “But there’s nothing specifically in the patent that says ‘Inspect this part a lot more than you inspect that one.’”