Amazon’s Factory Robot Patent Could Fight Understaffing

This kind of patent is particularly significant amid the company’s ongoing battles with workers aiming to unionize.

Sign up to uncover the latest in emerging technology.

Amazon is making sure its warehouse robots have enough juice.

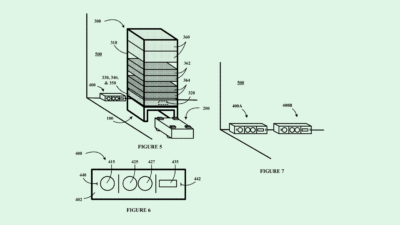

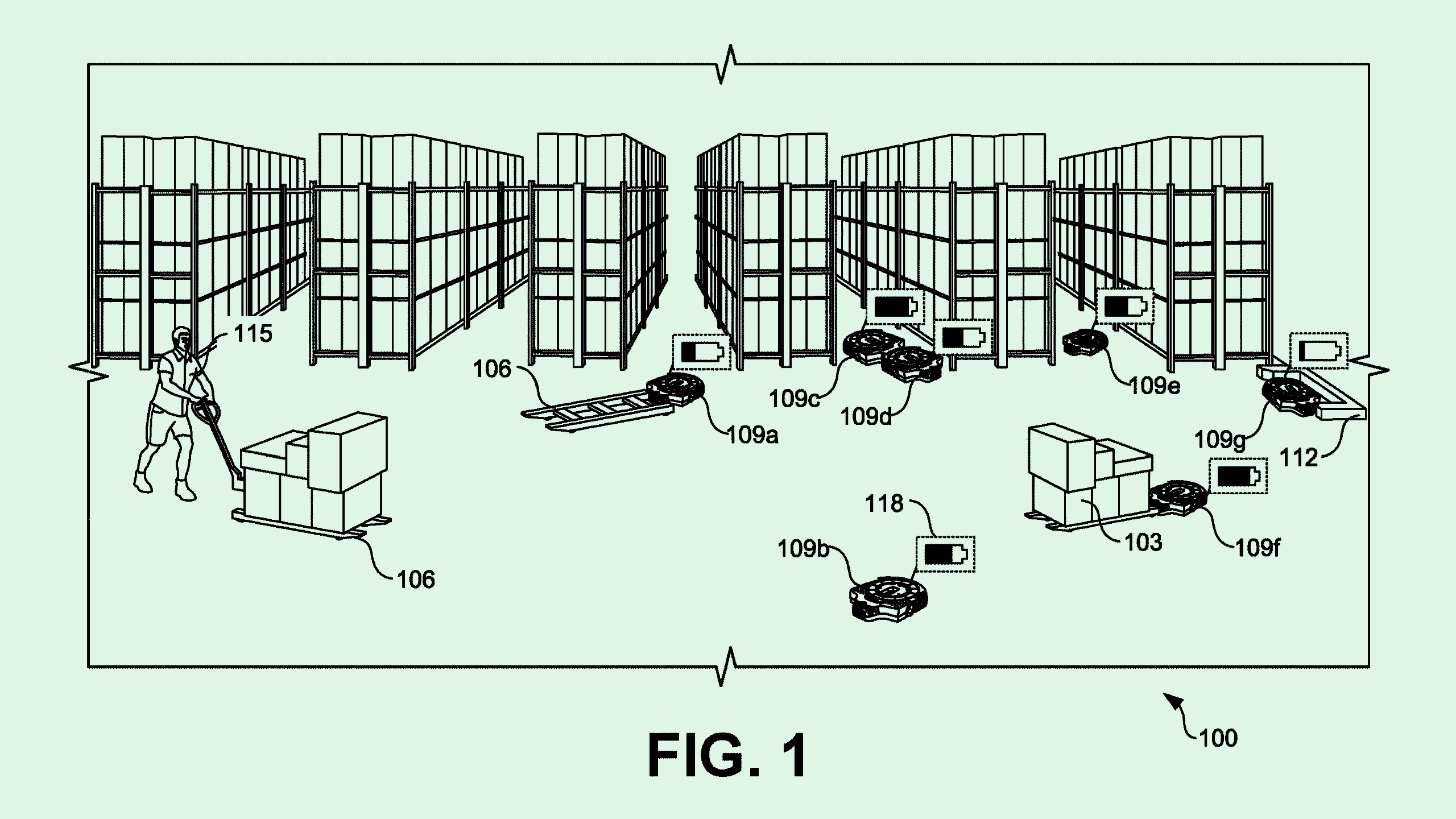

The e-commerce giant filed a patent application for mission assignment based on “battery charge state” for autonomous mobile robots. Amazon’s system aims to optimize use of self-piloted robots in logistics and warehouse spaces by taking into account a number of different factors, both looking at environmental data and the robot’s internal data.

Because tasks given to autonomous machines can vary greatly in time and intensity, it’s important to “maximize robot utilization (e.g., the amount of time a particular robot is in service vs. time spent charging) and potentially reduce the number of robots in a given fleet,” Amazon said.

Amazon’s tech monitors “mission data,” i.e., tasks to be completed within a facility, and data associated with the robots that complete those tasks, paying attention to charge states in particular and assigning tasks based on how much charge the robot has left. For example, if a robot has a high amount of battery left, they may be assigned to missions that take longer or require more movement.

Along with considering a robot’s battery life, the system will take into account a host of other factors, including mission priority, the robot’s task capability, “passing events” and “stop events,” and battery health. It also includes historical data relating to the facility itself into its calculations, including which areas of the factory floor tend to be congested and what missions are already being performed.

Amazon’s filing represents a common theme in the warehouse, logistics and factory space: All major manufacturers are going after “lights-out” production, a style of operation in which no humans are involved, including supervisors, said Rhonda Dibachi, CEO of Manufacturing-as-a-Service company HeyScottie.

And because warehouses historically faced a shortage of workers, “Every large manufacturer or distributor in the United States is going towards robotics,” said Dibachi. “Any (patent) that’s related to robots … is going to be useful for large distributors and large manufacturers.”

This patent in particular is going to be best put to use in a facility with a large fleet of robots to track, said Dibachi. That, however, isn’t a problem for Amazon — it operates dozens of fulfillment centers around the country, and has a facility in Massachusetts that can pump out up to 1,000 robots a day.

And while this patent is seemingly limited to materials-handling facilities, it’s not the only indication that this is the direction factories are heading. Automakers are also poised to accelerate robotics deployment as the cost of labor and union contracts rise.

Filling a factory with robots is an expensive endeavor, but the cost for deployment can end up being lower than the cost of labor, said Dibachi. By adding robots to factories, operators are aiming to utilize “the minimum amount of labor” possible, she said. “Labor is expensive. And you can’t inventory labor, but you can inventory your robots and deploy them as needed.”

This kind of tech is particularly significant coming from Amazon, given the company’s ongoing battles with workers aiming to unionize. Patents like these may signify that it’s looking at a robot workforce as a potential solution.